Description

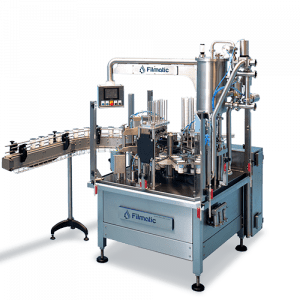

Designed to meet the most demanding requirements of forming, filling, and sealing liquid, semi-liquid, or pastry food products.

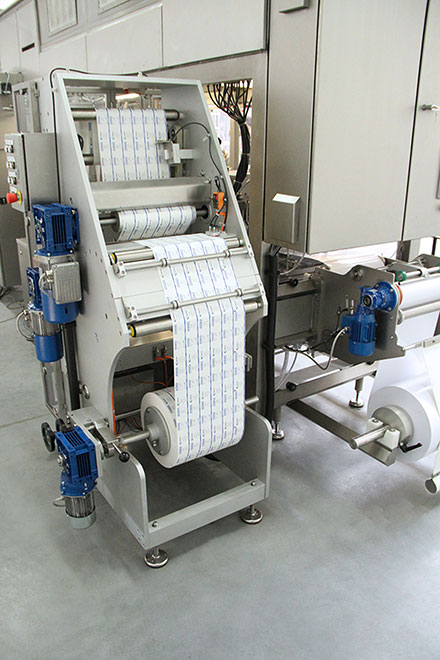

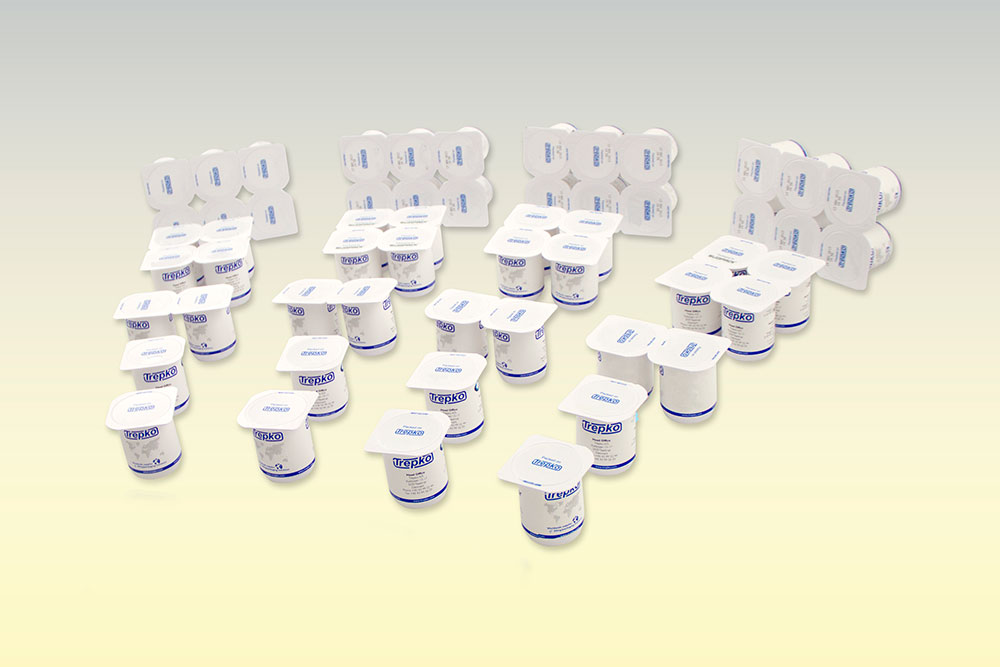

The TREPKO 9100 Series Inline Form Fill Sealing Machine offers a competitive solution designed to meet customer demand, offering a flexible, compact, hygienic, economical, and easy-to-use system. The machine achieves outputs from 3,000 up to 50,000 cups/hour, while at the same time keeping the floor space requirements at an absolute minimum. This makes the machines of the 9100 series the most compact solution on the market.

The standard version of each machine can have four filling stations connected, so you’re able to fill up to four different flavours in each cluster pack.

Filling applications: Yoghurt, cream, kefir, cream cheese, processed cheese, quark, desserts, jam/marmalade, honey, sauces, mousse, puree, conserve