Pasteurisation

Pasteurisation is the process of heat treating a product to ensure that it is safe for human consumption and to increase the shelf life of the product.

There are several trusted forms of pasteurisation, LTLT or Low Temperature Long Time, HTST or High Temperature Short Time, Tunnel pasteurisation and HPP or High Pressure Pasteurisation, plus other emerging methods.

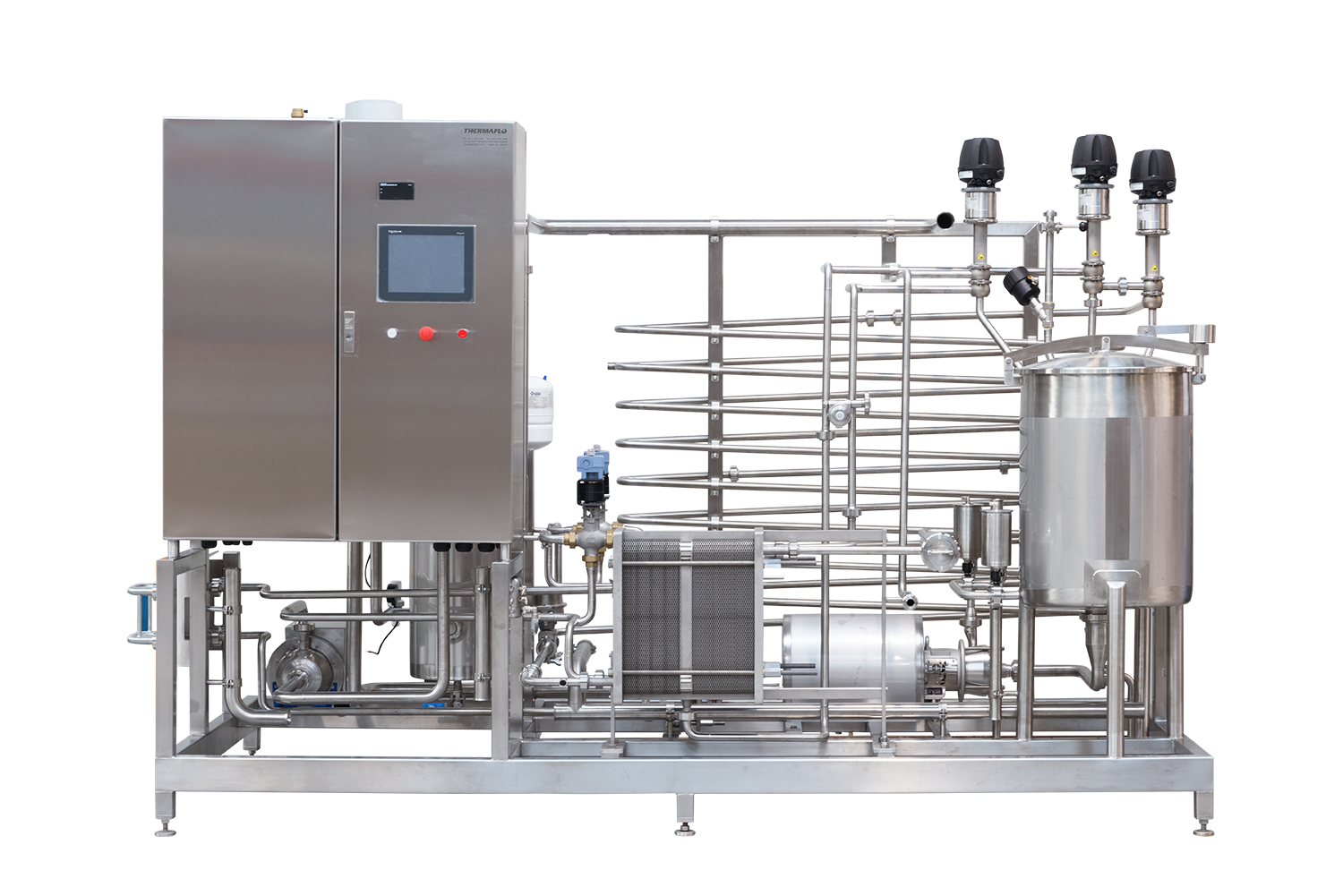

Depending on the product you are pasteurising and what the intended end product is, each pasteurisation process requires it’s own specific design. We use either a plate heat exchanger (PHE) or a tubular heat exchanger (THX) depending on the product to be treated.

Thermaflo has had a long-standing tradition to supply top quality, efficient pasteurisers that are specifically designed to meet you process needs.

Our systems range from as small as 150L batch pasteurisers (LTLT) to an excess of 50,000L per hour pasteurisers (HTST).

Specialising in pasteurisation, the team at Thermaflo have a wealth of knowledge when it comes to developing a pasteuriser for your individual requirements.

Whether the product is milk, cream, juice or even egg yolk or other difficult to pasteurise products, we will design a solution for you.

Questions?

Our process team are here to help!

Please contact us on 06 777 5300 or through our contact form.

“Thermaflo have worked for TruBlu since 2013, during this time they have designed, fabricated, supplied and commissioned several projects.

These include 3 x HTST pasteurisers for our QLD, NSW and WA plants, secondary modifications to our WA pasteuriser and a CIP Kitchen for our NSW plant.

What impresses us here at TruBlu is that Thermaflo are able to understand our requirements and translate these into integrated process plant solutions that are highly functional and competitively priced. We enjoy working with the staff at Thermaflo as they are responsive, knowledgeable and committed to providing the best outcomes for us.

Most of the projects we have engaged Thermaflo to supply have been within tight time frames and they have always delivered on time and to budget.

All of the above projects have gone very well with successful delivery and commissioning of the plants.

In summary, Thermaflo have performed to or above our expectations, I would engage them again for future projects and would happily recommend them to others.”