CIP Kitchens

As food and beverage manufacturers, our clients demand the highest of standards when it comes to plant hygiene & CIP.

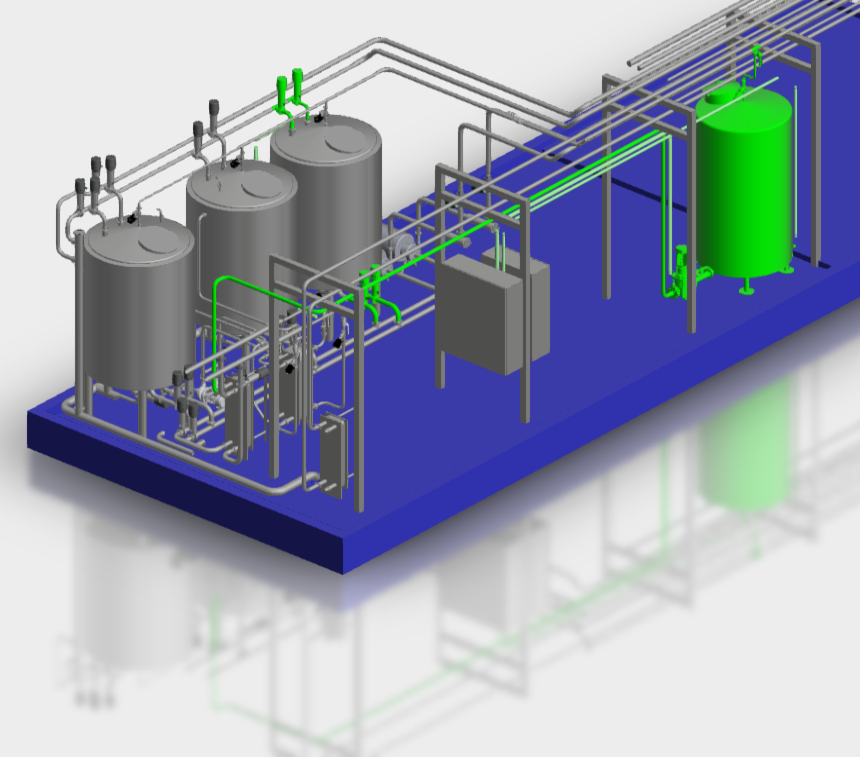

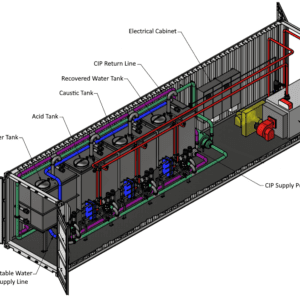

Our CIP systems are designed from entry-level, where a high degree of operator input is required, right through to complete fully automated CIP kitchens with multiple circuits to wash several areas of the plant at once.

For any CIP applications, we have the expertise to design a system that delivers your plant cleaning requirements. We have several options to suit your budget without compromising your plants hygiene. We can also stage your CIP project to assist with reducing the initial capital cost.

We take a holistic approach to plant hygienic design, this includes making sure there are no dead legs in the pipework, that road tankers/storage/buffer tanks and vats are designed correctly to ensure that they can be washed and that hot surfaces are washed correctly.

Why Choose A Thermaflo CIP System?

Built For NZ/AU Businesses To NZ/AU Standards Our CIP systems are designed and built here. You are guaranteed top quality with comprehensive testing to ensure a durable and easy to use CIP kitchen.

Custom Made Or Pre-designed

You can choose one of our pre-designed CIP kitchens to reduce cost your cost, or we can tailor to your processing situation.

Built For Efficiency

Our CIP kitchens are designed to reduce chemical and water usage, lower cleaning times and reduce your overall cleaning costs, as well as enhancing operator safety.

Simplified By Automation

Our equipment controls are fully automatic and will deliver the correct cleaning variables of time, temperature, and chemical concentration. The Automated controls will also manage correct solution velocities and pressures to ensure a successful cleaning regime.

Questions?

Our process team are here to help!

Please contact us on 06 777 5300 or through our contact form.

“Talking with Thermaflo they provided us with a proposal for a fully automated CIP kitchen that was designed to ensure the correct cleaning variables of time, temperature and chemical concentration would be delivered to our new plant at the correct velocities and pressures to ensure a successful cleaning regime for the new process.

Thermaflo have done an outstanding job on the project and with the increased capacity of this CIP kitchen, we will be able to start expanding the rest of our process. We always like working with Thermaflo and will happily recommend them to others. “