Separation & Decanting Equipment

Centrifugal separation solutions are saving time and money for dairy producers, brewers and winemakers around the world.

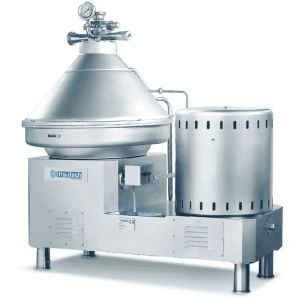

Frautech Separators

Centrifugal separators are high-efficiency machines that separate, clarify, concentrate and purify, adding to your yield and productivity, and ensuring reliable performance and lower total operating costs – year after year.

With over 100 years of experience in centrifugal separators, Frautech is a leading name in separation for food and beverage processes.

Separators are installed in plants around the world to; separate whole milk into skim milk and cream, standardise milk fat, remove bacteria, remove yeast and solids from beer/wine/cider/kombucha and stocks.

Separator Applications:

- Dairy

- Milk clarifiers

- Milk fat standardiser

- Bacteria removal clarifiers

- Cream Separators

- Nozzle separators for yoghurt and soft cheeses

- Cream concentration

- Kombucha clarification

- Beer / Wine / Cider clarification

- Stock / Bone Broth clarification

Benefits of Frautech Separators:

- High g-force for outstanding separation efficiency.

- Large solids space for longer time intervals between discharges.

- Liquid ring sealing for reduced oxygen pickup.

- Sturdy construction, made to ensure long-lasting operation.

- Ease of maintenance.

- Soft start and soft speed recovery after discharges, reducing mechanical stress and wear.

- High-grade finish on all surfaces for easy cleaning.

- Extremely simple design ensuring:

- Outstanding reliability

- Reduced operating costs

- Reduced noise

- Lower maintenance costs

- Low total cost of ownership

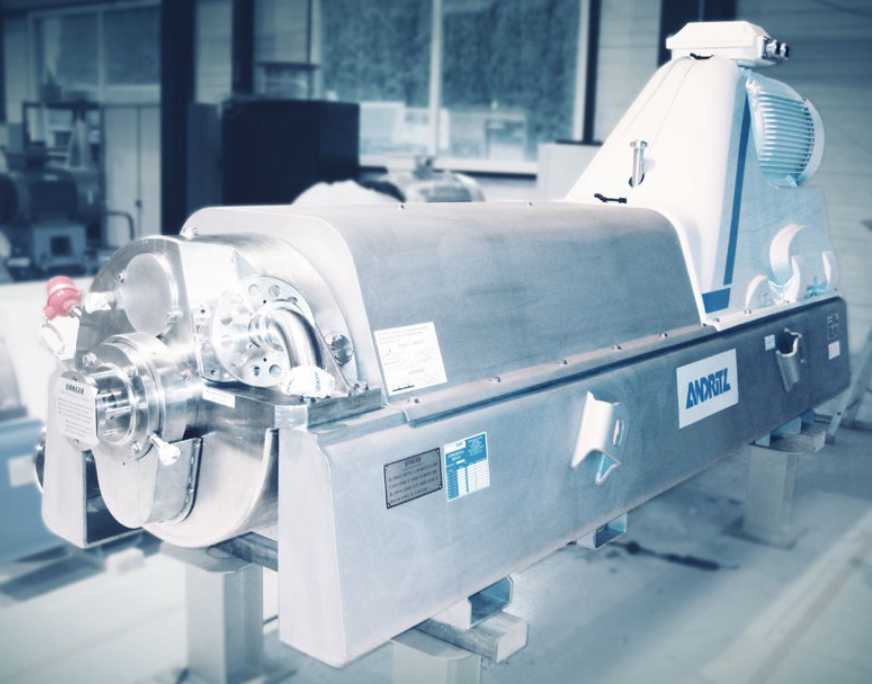

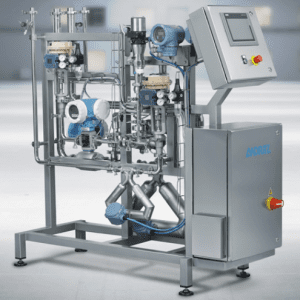

ANDRITZ Decanters

With more than 15,000 decanter centrifuges installed around the world, ANDRITZ Separation is one of the global leaders for the supply of decanters. The ANDRITZ decanter centrifuge “F” is designed especially for the food industry meet the most demanding requirements.

Decanter Applications

- Beverage extraction

- Wine

- Juice

- Beverage solids reduction

- Juice

- Wine

- Plant-based dairy alternative

- Oils and fats

- Dairy

- Casein

- Lactose

Benefits of ANDRITZ Decanters:

- Three machines in one: heavy or light phase discharged under pressure and two-phase machine with plugs for more production flexibility

- Low oxygen pick-up due to discharge under pressure from a hermetically sealed chamber

- Special feed chamber, ensuring gentle treatment of your product

- Modular design to accommodate your requirements

- Maximum security with vibration, bearing temperature, and motor probes, washing nozzles integrated into the frame

- Low maintenance cost and easy dismantling with unique inline design

- Long service life due to robust design and high-grade materials

Questions?

Our process team are here to help!

Please contact us on 06 777 5300 or through our contact form.