Dairy Process

We have tremendous experience in the design, manufacturing, installation and commissioning of dairy process lines for liquid dairy products.

We have worked with a wide range/scale of businesses from farmers wanting to produce their own milk/cream for local distribution, right through multi-national dairy manufacturers.

Our prior projects include:

- Fresh milk and cream process lines

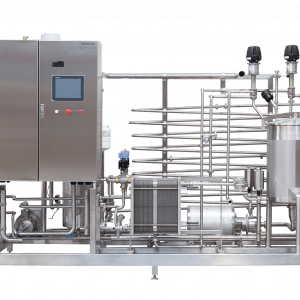

- Extended or UHT shelf life process lines

- Yoghurt process lines

- Cheese production

- Ice-cream production

- Butter churning/wrapping

- Process consultancy for new product development

- Pilot plants for new product

- Milk process plant upgrades

We’ll provide specifications, as well as supply those essential services such as boilers for steam or hot water, cooling systems such as water/glycol chillers or cooling tower water, as well as factory positive air and ventilation systems.

Using our extensive knowledge and experience we also advise our clients on important things such as sub-floor drainage, flooring coatings, flooring coving, general principles for a hygienic environment, complete factory layouts and floor plans etc.

Questions?

Our process team are here to help!

Please contact us on 06 777 5300 or through our contact form.

Dairy Projects Completed Since 1992

Years Since We Built Our First Pasteuriser

-

Ageing Tanks

-

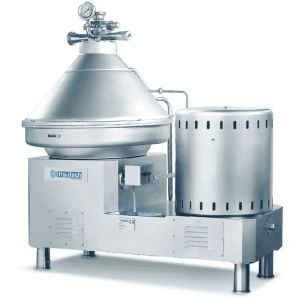

Bacteria Removal Separator

-

Batch Pasteurisers

-

Cheese Vats

-

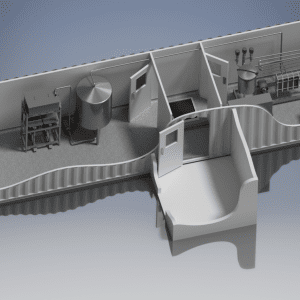

Containerised Process Plant

-

Cream Separator

-

Direct Steam Injection UHT/HTST

-

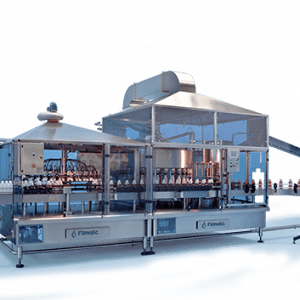

Filmatic ESL Bottle Filling Machine

-

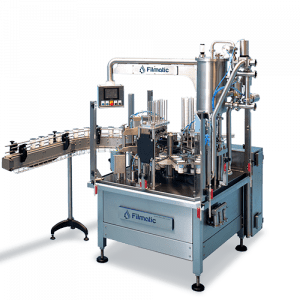

Filmatic Index Tub Fillers

-

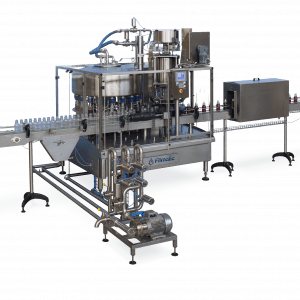

Filmatic Rotary Bottle Filling Machines

-

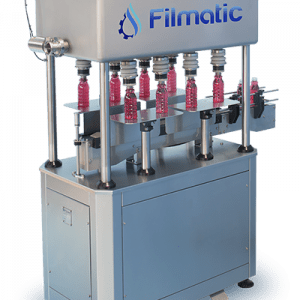

Filmatic Semi Automatic Bottle Filling Machine

-

Fruit Dosing Machines

-

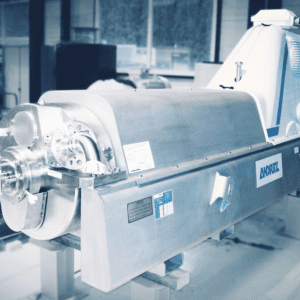

Homogenisers

-

Ice Cream Churns

-

Ice Cream Ingredient Feeders

-

Ice Cream Mix Plant

-

Ice Cream Ripple Pumps

-

Ingredient Blending, Mixing & Dosing

-

Inline Pasteurisers

-

Lab Scale Homogenisers

-

Lattomatic Milk Standardiser

-

Limitech MY Mix Lab Scale Mixer

-

Limitech P Series Mixers

-

Limitech S-Series Mixers

-

Linear Ice Cream Cup Tub & Cone Filler

-

Milk Separator

-

MilkyLab Cheese Plants

-

Milkylab Pilot-Scale Cheese Systems

-

Positive Displacement Pumps

-

Product Reception

-

Rotary Ice Cream Filler

-

Semi-Automatic Ice Cream Filler

-

Tanks & Vessels

-

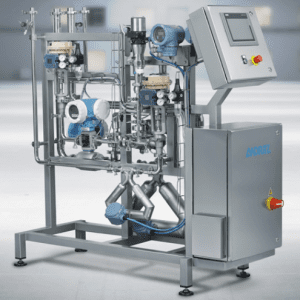

Thermaflo Pilot Systems

-

Trepko Carousel Tub Filling Machines

-

Trepko Inline Aseptic Filling Machine

-

Trepko Rotary Tub Filling and Closing Machines

-

Trepko Semi-Automatic Tub Filling and Closing Machines