ESL & UHT Milk Processing

An Extended Shelf Life process involves heating the product to above 135°C to sterilise it.

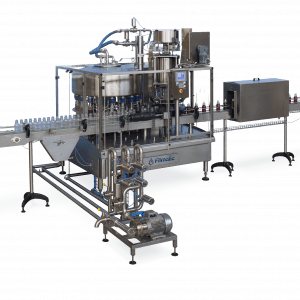

With high heat treatment processes, an aseptic environment, and specialised equipment – made to the highest possible food safety standards – is critical to avoid re-contamination.

Hygenic design is vital from the initial design process right through to the install and cleaning systems.

| Products | All types of fresh milk, low / high fat, cow, buffalo, sheep, goat |

| Inlet Temperature | 4 Deg C – Any |

| Processing Temperature | 135 Deg C to 144 Deg C |

| Outlet Temperature | Any – 4 Deg C |

Typical UHT Process Steps:

- Raw milk reception, pumping, cooling and storage – Our solution will take into account tanker unloading times, daily volumes, incoming raw milk temperature and required raw milk storage.

- Heat treatment – Thermaflo will design the indirect or direct heat treatment plant to process your product to meet your required shelf life. Typically each UHT unit is a one-off to meet the specific needs of the individual client.

- Separation / Standardisation – Depending on the required fat level of the finished product, a separator/fat standardisation system can be included at the heat treatment stage.

- Homogenisation – A homogeniser is included in-line. This will be either a standard homogeniser or an aseptic version depending on the process.

- Buffer tanks – The design can include an aseptic tank to balance the product flow prior to filling.

- Aseptic Fillers – Depending on the type of packaging and the flow rate required, we will supply and install a suitable filler whether this is a brick style pack or bottle.

Our Capabilities

- Process Design – Our design team will spend time understanding your needs and expectations, then translate this into the technical design for their UHT milk plant.

- Electrical control / Automation – We design and build the electrical control panels for the process plant. By doing this we take responsibility for the interface of the plant and this enables us to deliver the complete integrated solution.

- Site installation – Thermaflo will design and install the stainless-steel pipe work for your product, CIP, SIP, steam and chilled water, plus compressed air lines and stainless-steel electrical conduit, all to the highest quality and to strict hygienic standards. Much like the electrical control, the pipe work design is a critical component of the integrated process system.

- Commissioning and Training – We provide a full commissioning and training service to support the project.

- After-sales support – This includes both preventative maintenance service support on a scheduled programme as well as on the phone support for the operators and local trades e.g. the electrician.

Questions?

Our process team are here to help!

Please contact us on 06 777 5300 or through our contact form.