Yoghurt & Fermented Products

- Home

- /

- Process Solutions

- /

- Dairy Process

- /

- Yoghurt & Fermented Products

Yoghurt and Fermented products have been in our diet for centuries, and they are extremely popular today with many recent innovations.

At Thermaflo, we know what it takes to create a quality cultured product. Whether you are looking for a traditional pot set or stirred yoghurt, kefir, cultured butter or cream products, we will develop the process that will produce a quality product.

Case Study: Epicurean Dairy

We’ve worked with the team at Epicurean Dairy / The Collective for nearly 20 years, across dozens of projects – large and small.

Click here to read about some of the projects we’ve completed for Epicurean Dairy

| Products | Pot set yoghurt, stirred yoghurt, drinking yoghurt, Greek yoghurt, etc |

| Batch Size | 150L Per Batch – 10,000L Per Batch |

| Process Flow Rate | 150L Per Batch – 20,000L+ Per Hour |

| Inlet Temperature | 4 Deg C – Any |

| Processing Temperature | 80 Deg C – 95 Deg C |

| Outlet Temperature | 30 Deg C – 50 Deg C |

Process steps:

- Ingredient mixing: the various components are incorporated into the mix and hydrated at the correct temperatures, i.e. powders, sugars and liquids.

- Heat treatment: taking the type of yoghurt to be produced into account, we design the pasteuriser specifically to achieve the correct temperature and holding time.

- Culture addition, fermentation and cooling: whether you are fermenting in tank or in the final product tub, our design will allow the perfect product to be made. We also have a great system for inline cooling for stirred yoghurt that doesn’t affect the final curd structure.

- Fruit Dosing (if required): we can supply a solution that will dose and dynamically mix fruit into yoghurt in a continuous process or a static mixing solution.

- Filling: We supply suitable fillers specifically built to cater to your product requirements and filling speeds. This could be an entry-level filler right through to a machine that will give you a multi-layered fruit/product presentation with a dry ingredient on top.

Over the years, we’ve worked on, and designed, projects both large and small, and we’ll tailor-make a solution for your processing requirements.

-

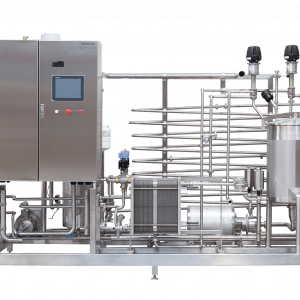

Batch Pasteurisers

-

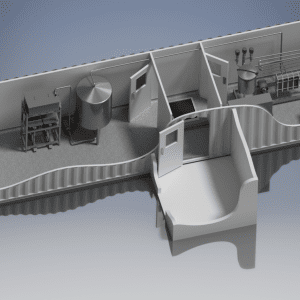

Containerised Process Plant

-

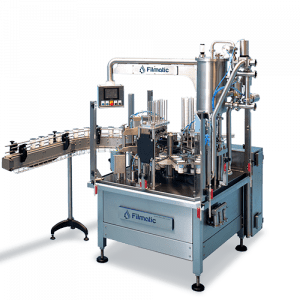

Filmatic Index Tub Fillers

-

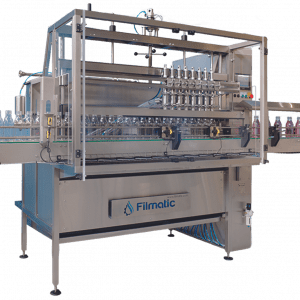

Filmatic Inline Piston/Pump Filler

-

Fruit Dosing Machines

-

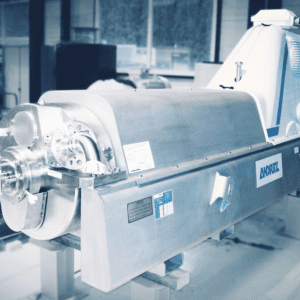

Homogenisers

-

Incubation Tanks

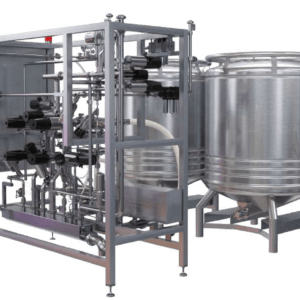

-

Ingredient Blending, Mixing & Dosing

-

Inline Pasteurisers

-

Limitech MY Mix Lab Scale Mixer

-

Margarine & Spreads Processor

-

PCM Dosyfruit™

-

Positive Displacement Pumps

-

Product Reception

-

Tanks & Vessels

-

Trepko Carousel Tub Filling Machines

-

Trepko Inline Aseptic Filling Machine

-

Trepko Inline Form Fill Sealing Machine

-

Trepko Rotary Tub Filling and Closing Machines

-

Trepko Semi-Automatic Tub Filling and Closing Machines

Questions?

Our process team are here to help!

Please contact us on 06 777 5300 or through our contact form.

“…Through a competitive process, we settled on employing Thermaflo to deliver the design and plant. Thermaflo are well known to us as they have successfully delivered many projects to The Collective since 2008.

…The result is a truly great project, delivered on time, to budget and to our expectations, to date this is the best project that Thermaflo have delivered to Epicurean and this was achieved in tough circumstances due to Covid 19.

We are very happy with the plant and our senior management are delighted with the product it makes as such I have no hesitation to highly recommend Thermaflo’s skills to everyone.”